Before

- The volume of articles was set to nearly double, but it was difficult to hire more personnel, and the large volume could not be handled via current paper processing.

- Due to contract changes with clients, it became necessary to assort articles quickly the same day that they were delivered.

- It was difficult to physically place wired put-to-light systems for handling paper products and large objects like clothes-drying poles.

- Put-to-light systems for simultaneous work by several workers carry the risk of workers’ accidentally pushing a button of the wrong color.

After

Because of an increased efficiency in assorting articles, it was possible to handle an increased amount of goods and decrease lead times without additional personnel.

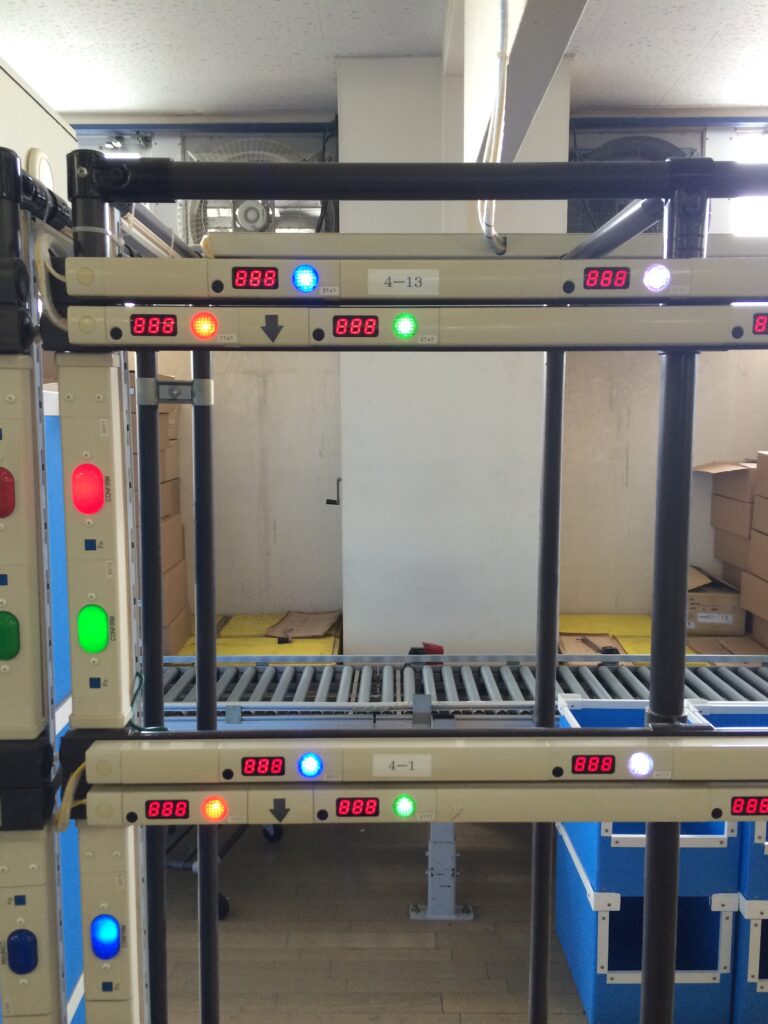

- By utilizing the flexibility of Wireless Light Modules and adapting floor layouts, work planned in multiple batches could be finished as a single batch, increasing efficiency.

- Five-colored Multi-Work Light Modules allowed simultaneous task processing by five workers. Simultaneous tasks were carried out by multiple workers without color-coding mistakes, by checking goods via barcode scanners and without pressing a button on the Light Module after completion of each task.

- Because workers did not have to carry pencil and paper, they were able to work more quickly.